On the fracture mechanics validity of small scale tests

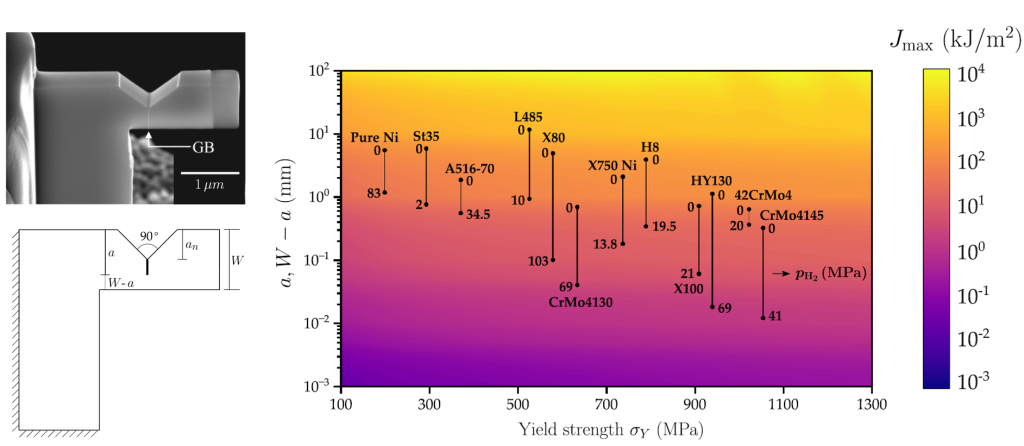

There is growing interest in mechanical micro-scale experiments, which can be combined with in-situ microscopy to gain new insight into the interplay between crack growth and microstructural phenomena (e.g., dislocation behaviour or the fracture resistance of a particular interface). However, for these experiments to be quantitative, the sample needs to be large enough for the relevant fracture parameter (J-field) to exist. In this work, numerical simulations are conducted to determine the sample geometry that would enable a direct, quantitative estimation of fracture resistance – i.e., a valid fracture test. Maps are built to cover a wide range of material properties, crack lengths and specimen dimensions, determining for each of these conditions what the maximum load should be. Moreover, the analysis is extended to the case of metals exposed to hydrogen, an area of notable technological importance. The findings enable the design of optimal micro-scale experiments, which favour cracking (vs plastic collapse) and can lead to quantitative estimates.

Authors: Chuanjie Cui, Livia Cupertino-Malheiros, Ziyao Xiong, Emilio Martínez-Pañeda